Sustainable Manufacturing using Bioresin for Low Carbon Vertical Farms

The project partners wanted to find out if proven bioresin from agrifood waste processing could be used to build vertical farm towers, potentially reducing the carbon footprint of the towers and enabling innovative design concepts.

Building the Circular Bioeconomy: Scaling Sail Upcycling

Sustainable Extricko is developing a closed loop recycling process for petrochemical derived materials like sails, with the goal of integrating end-of-life (EoL) sails into the circular economy.

In this project, they wanted to characterise microbial growth and tolerance to sail recyclates and optimise fermentation conditions to progress this technology towards scale-up and industrial application.

Characterisation and extraction of valuable components from marine growth

There’s limited knowledge about the potential value of marine growth on decommissioned offshore assets. CessCon Decom wanted to characterise the nutritional composition of the marine growth and assess the feasibility of extracting valuable components.

Microbially mediated biological treatment of primary effluent from H2OPE fertiliser production

This project investigated the feasibility of miniaturising and optimising the biological treatment of the wastewater effluents from SEM biofertilizer process.

Recycling and remediation of metal from advanced alloy waste

High-performance steels and alloys necessary for modern applications comprise of a plethora of valuable and critical metal resources such as nickel, cobalt, tantalum, niobium, and rhenium, which are currently poorly recycled. SEM wanted to look at potential routes to the recovery of metals which can then be re-used.

Improving the sustainability of resins and films with natural lignin derived from biomass residues

Lignin is a material obtained from woody biomass, such as forestry waste suitable for a range of applications. Sonichem wanted to investigate the feasibility of using their natural lignin in the production of advanced, bio-based and sustainable films and resins in packaging and composite manufacturing.

Separation of Organic Platform Chemicals from Spent Lees

Successful project to assess the feasibility of extracting platform chemicals from spent lees delivers a valuable new feedstock, a bespoke analytical tool, additional product streams and evidence to substantiate the company’s green credentials.

Determining the Antimicrobial Efficacy of CuanTec’s Technology

Funding from IBioIC enabled CuanTec to work with Abertay University to determine the antimicrobial efficacy of the company’s proprietary chitosan based prototype formulations

Selection and characterisation of anti-peptide synthetic antibodies for comparison with conventional reagents

This Feasibility funded project developed two antibodies using biopanning of University of Edinburgh’s phage display library, allowing TAC to successfully apply for further funding to advance the project and bringing potentially significant benefits for the Scottish economy.

Producing broad spectrum antiviral therapeutics from cyanobacteria

In this successful Feasibility Project, the project partners identified antiviral therapeutics that can be extracted from cyanobacteria, and gained leverage for additional funding, training opportunities, and developed new methods for fractionating and purifying polysaccharides.

A novel plant enzyme for enhancing the viscosity or hydrophobicity of cellulosic materials

Proof of concept was achieved in this Feasibility project to improve the strength and water repellent properties of Cellucomp’s paper-based packaging materials.

Determination of crustacean allergens in purified chitosan through interlaboratory assessment

IBiolC Feasibility funding enabled CuanTec to access the analytical capabilities of the University of the Highlands and Islands to accurately determine the presence of allergens in CuanTec’s purified chitosan.

Exploring the Feasibility of CuanTec’s Process By-products as Sources of Added Value

In this Feasibility project, CuanTec Limited and James Hutton Institute teamed up to analyse the value of side streams from crustacea shells.

Optimising light wavelengths in algal bioreactors

With funding from IBioIC, researchers from St Andrews and Xanthella Ltd have undertaken a feasibility project to improve the production of industrial feedstocks by microalgae under solar illumination.

Microbial production of hydroquinone from waste feedstocks

IBioIC funded a joint project between Victrex and Joanna Sadler and Stephen Wallace from the University of Edinburgh to explore alternative, more sustainable routes for the production of Hydroquinine, ideally from renewable or waste feedstocks, to contribute to their goal of carbon neutrality by 2030.

Extending the analytical capability of affordable Microbioreactors

ŌGI Bio Ltd wanted to explore the feasibility of utilising the University of Edinburgh’s state of the art in-line dilution technology to extend the valid range of OD measurements for their microbioreactors.

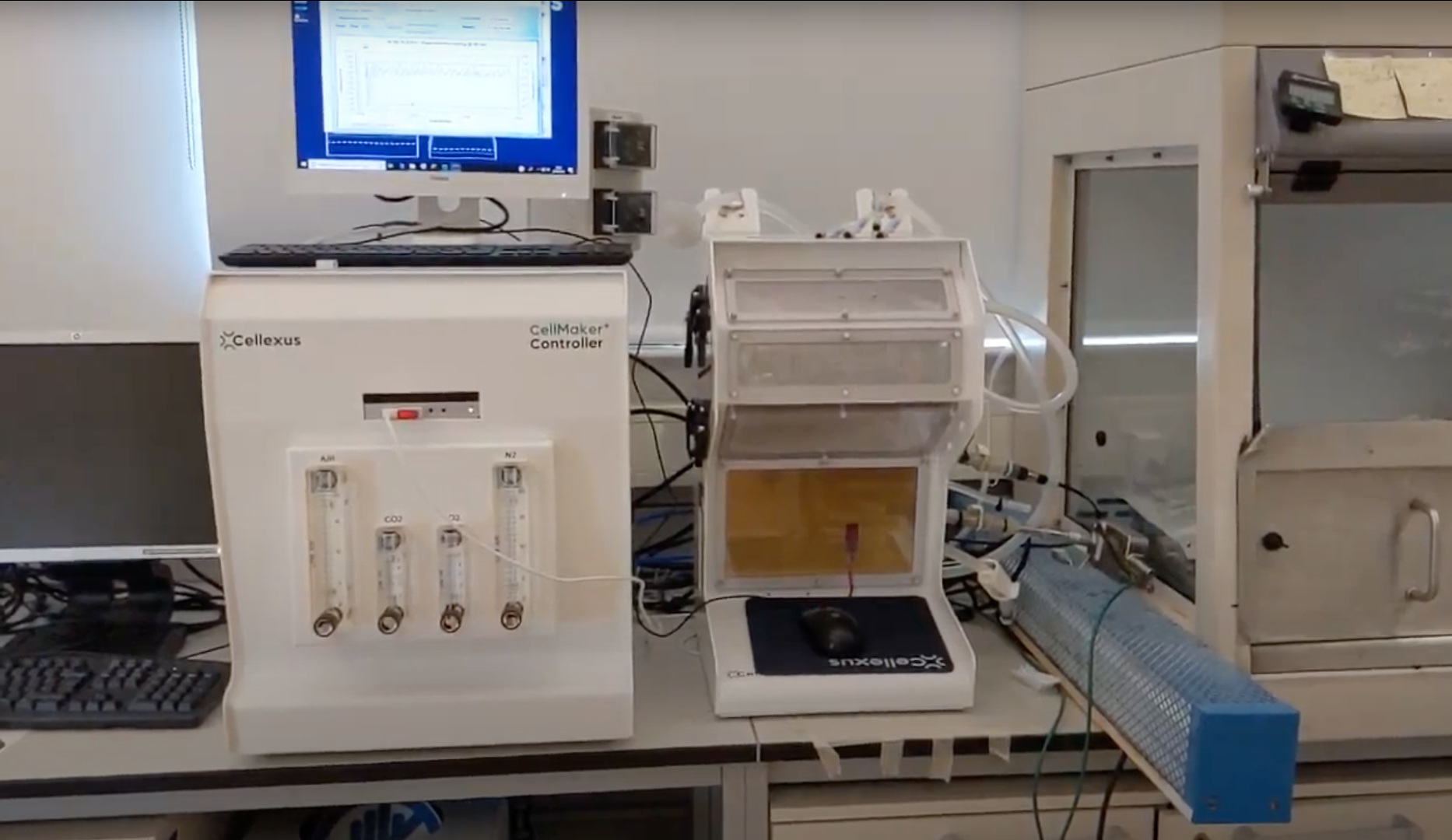

Using a Single Use Airlift Bioreactor to produce recombinant monoclonal antibodies (mABs) in mammalian cells.

This Feasibility project sought to obtain data on whether and how the CellMaker aids the growth of mammalian cells for use in the production of medicines, therapeutics and research reagents.

Fish oil waste source for the production of bio based surfactants

This project investigated the feasibility of using oils extracted from fish industry waste to produce ingredients such as detergents and foaming agents for use in industrial products.

Analytical techniques for fungal morphology and nutrient feed composition in a food application

Improving the process for making sustainable meat alternatives at scale.

Commercial Chitosan Conversion

Trialling techniques to assess the chemical properties of chitosan extracted through a novel process.